Production Logging

What

Is Production Logging?

Production

logging consists of running logging tools in both production and injection

wells. They can be run under dynamic

(flowing) or static (shut in) conditions.

With proper interpretation, production type, production intervals, and

flow rates can be determined.

Production logging can be identify:

1. Water

entry/exit locations and sources

2. Non-performing

perforations

3. Flow

behind casing or tubing

4. Crossflow

5. Leaks in

tubing or casing

6. Unproductive/receptive

intervals for stimulation

7. Packer

leaks

8. Lost-circulation

zones

You may

use PL on your injectors or you may use it on producers that are communicating

with or in the vicinity of injectors.

For this reason, the discussion is kept generic, at least initially, so

that the relevant concepts for either application can be appreciated. Typical components in PL surveys are

summarized below. There are variations

in the degree of sophistication of these measurements (and tool configurations)

from vendor to vendor but the concepts remain the same.

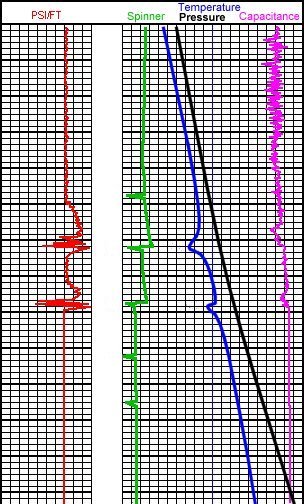

Temperature

The

temperature sensor measures the temperature of the borehole. Temperatures logs were one of the first

production logs and are still widely relied on today to qualitatively (and

sometimes quantitatively) yield a variety of information. One of the primary uses is for fluid entry

identification from the change in temperature that normally occurs when fluids

from different depths enter a wellbore during production or enter the formation

during injection. Temperature can be

used for injection evaluations although interpretation can be difficult.

Temperature

logs can indicate flow behind casing or tubing, such as channeling (use

standard surveys as well as warmback measurements!). Other applications include locating gas entries, defining lowest

point of production or injection, identification of casing, tubing, or packer

leaks, checking gas-lift valves, defining the geothermal gradient, locating

lost-circulation zones, determining hydraulic fracture height (approximately at

least), and defining cement placement and top.

Pressure

The

pressure sensor measures the pressure in the borehole on a depth-to-depth

basis. While logging, change in

pressure versus change in depth is used to determine the pressure gradient (and

consequently density) in the wellbore.

This can be used to identify gas, oil and water interfaces during

production. The pressure sensor can

also be used to determine wellbore pressures for critical well control

applications, to evaluate friction losses and for a early time buildup when

well is shut-in prior to making shut-in logging passes. As a fluid density device it can be used for

fluid identification, fluid entry or exit point determination and water holdup

determination if there is gas production.

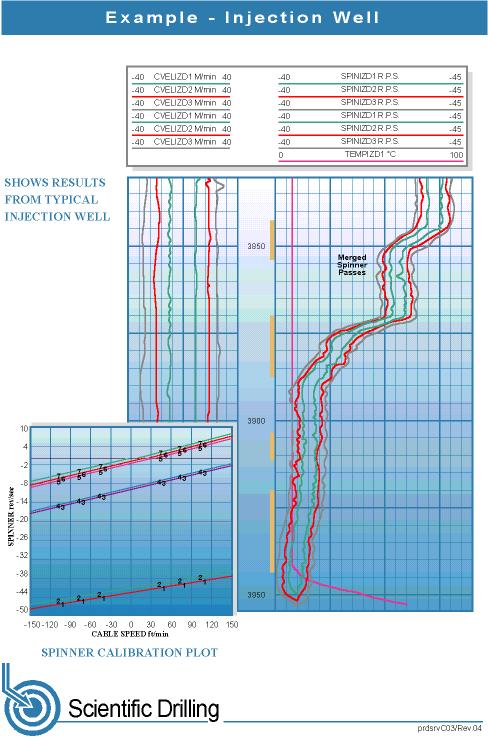

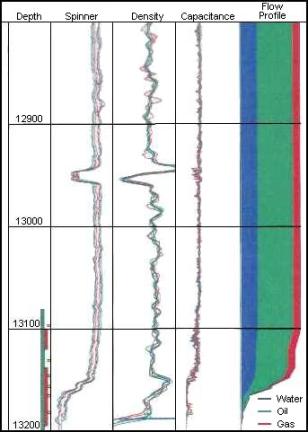

Spinner

Flow

along the wellbore is measured, commonly with a spinner. The spinner is a fan blade type device that

is rotated by the fluid movement in the borehole. Many new-generation spinners have diagnostics that determine the

flow rate and flow direction and also detect any problems in the system and

will correct the flow rate automatically if there is a tool error.

The

spinner response is typically linear with production velocity, but is offset

from the zero point. This is due to the

friction in the spinner's bearings as well as the viscosity of the production

fluid and is called the spinner threshold.

To get good results from the spinner survey, the borehole flow rates

should exceed some minimum value (e.g. 10 feet per minute in fluid or 28 feet

per minute in gas). Charts are

available to convert production in barrels per day to flow rates in different

sizes of pipe. The tool velocity also

adds or subtracts from the spinner rate and is used to calibrate the spinner

and determine the spinner threshold. Line

speed is a critical component in most production logging. It is important to remember that the spinner

is only indicating what is happening in the borehole where the spinner is

positioned and that the production dynamics of boreholes may vary greatly,

causing the spinner to sometimes give unreliable results especially in

multi-phase wells.

Dielectric (Water Holdup)

This is

used for inferring components in the production stream and, for PWRI, would be

more useful in an offset producer where water cut has increased. This is also referred to as the capacitance

sensor and measures the dielectric constant of the fluid in the borehole. Since the dielectric constant of water is

high (about 80) and that of oil and gas is low (2 -6), this sensor is used to

determine the fluid type, namely hydrocarbon or water. This sensor compliments the pressure

gradient. The difference in the

pressure gradient between oil and water is very small (0.09 psi), but the

dielectric values are greatly different, making the capacitance tool very

sensitive to small amounts of water.

However, the capacitance sensors response to percent of water mixes is

not linear and when water becomes the dominant percent of the mixture it becomes

difficult to discriminate any the percent of water and oil in the mix (some

sources indicate that the oil cut needs to be greater than 3% to be detected).

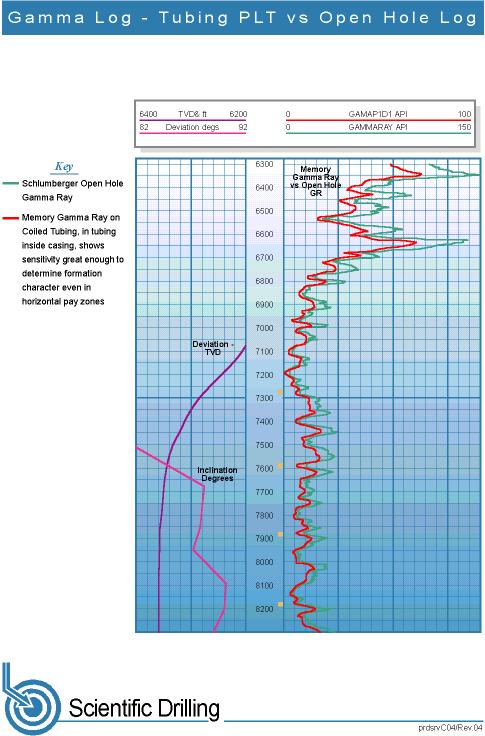

Gamma Ray

As is

well known, the gamma ray sensor measures natural radioactivity. The gamma ray is mainly used for adjusting

the depths of the production logs with other logs to a common basis. The gamma ray can also be used to follow

injected radioactive material in the borehole to determine flow profiles and

velocities and can be used to trace frac sand that has been tagged with radioactive

material.

Casing Collar Locator

(CCL)

The

casing collar locator (CCL) measures magnetic anomalies induced by changes in

metallic mass in the borehole. It is

also used as a means of depth correlation and can be used to locate

perforations, packers, x nipples, gas lift valves, screens, and other

mechanical components in the borehole.

Vendors

PL tools and services are

offered by a variety of vendors – with broad geographical coverage and levels

of sophistication. Appendix A is an

audit of some of these service providers.

It is only a partial list of vendors.

The products and services of the following vendors are summarized in the

Appendix. More information is available

from these service companies.

Vendors

(refer to Appendix A)

|

Company |

Location |

URL |

|

Baker

Atlas |

Worldwide |

http://www.bakerhughes.com/bakeratlas/reservoir_production/polaris_index.htm |

|

Cardinal

Surveys Company |

Odessa,

TX, Hobbs, NM |

|

|

Expro

International Group PLC 2001 |

Aberdeen

and other offices worldwide |

|

|

Halliburton |

Worldwide |

http://www.halliburton.com/spe98/flow2000.asp

|

|

Kuster

Company F.T.I. Inc. |

Long

Beach, CA and other worldwide offices |

|

|

Lee Tool Division of

Schlumberger Canada Ltd. |

Red Deer, Alberta |

|

|

Madden

Systems Incorporated[1] |

Odessa,

TX; Houston, TX; |

|

|

Maxim

Technology Limited |

Wales,

UK |

|

|

Oildata

Wireline Services Limited |

Port

Harcourt, Nigeria |

|

|

Read

Well Services |

Bergen,

Norway; Aberdeen,

UK; Doha, Qatar |

|

Schlumberger

|

Worldwide |

|

|

Spartek

Systems |

Sylvan

Lake, Alberta |

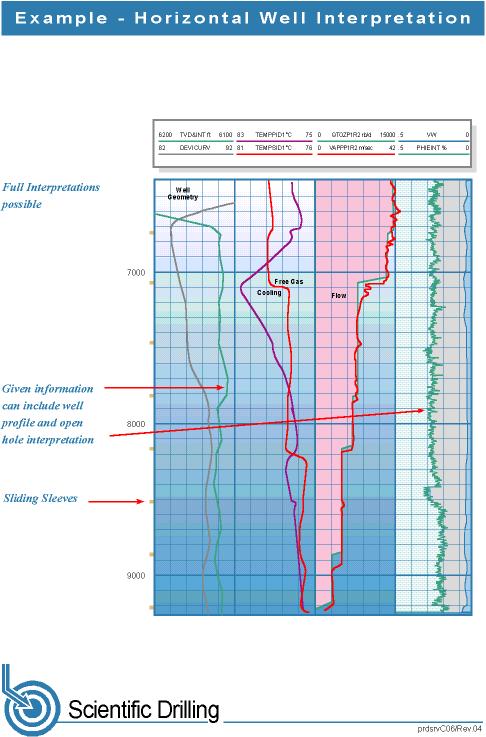

PWRI Specific Issues:

Many of the specific

difficulties occur when logging in horizontal or high angle wells, especially

if there are multiply fractured zones.

Warmback measurements can help to discriminate what the true entry point(s)

is (are).

Appendix A

PLT Service Providers

Baker Atlas

http://www.bakerhughes.com/bakeratlas/reservoir_production/polaris_index.htm

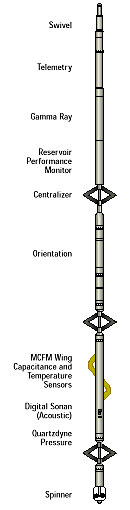

POLARIS System

|

|

The Baker Atlas

POLARIS System is a combination of the Reservoir Performance Monitor (RPM)

and Multi-Capacitance Flow Meter (MCFM) logging tools – a slimhole diagnostic

system for evaluating and understanding horizontal well and reservoir

performance. |

Reservoir Performance Monitor (RPM)

This

is a slimhole (1.7-in. OD) multi-function pulsed neutron tool. The RPM instrument combines multiple nuclear

measurements in one system.

Carbon/Oxygen (C/O) and pulsed neutron capture (PNC) measurements

acquired with the RPM tool provide water saturation and three-phase holdup

determination while oxygen activation measurements allow water flow and channel

detection. The small diameter

instrument addresses a broad scope of reservoir evaluation and management

applications, including reservoir saturation and produced fluids monitoring,

formation evaluation, production profiling, workover and well abandonment

evaluation, borehole diagnostics, locating bypassed oil, and identifying water

production.

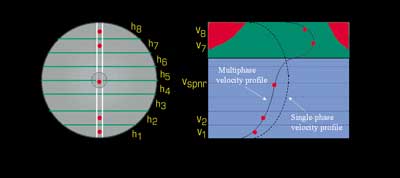

Multi-Capacitance Flow Meter (MCFM)

A

multiphase production logging tool for non-vertical wells. The small diameter, multiple-sensor MCFM

instrument incorporates technology for measuring three-phase flow – oil, water,

and gas – in horizontal, highly deviated, and undulating wellbores. The combination of an across-the-wellbore

capacitance array with temperature, pressure, and acoustic sensors allows the

MCFM instrument to pinpoint the location of three-phase fluid entry into the

wellbore. The MCFM tool can

simultaneously measures all three phases in multiphase flow.

With

most production problems, the location of unwanted fluid production is of

primary interest. However, to

completely solve the production problem, the source as well as the location are

needed; e.g., whether it is due to cresting or coning, depletion, fingering,

injection breakthrough, fractures or faults, or behind-casing flow. The POLARIS system, combining RPM and MCFM,

can go to the region of unwanted fluid production and operate in a

high-resolution logging mode to identify both the location and source of the

unwanted fluid.

Measurement

of multiphase flow behavior and inflow profile determination in horizontal

wells is possible with the Multi-Capacitance Flow Meter Service.

Polaris Applications

·

Reservoir monitoring and management

- Establish base logs and monitor fluid

contacts, production, reservoir depletion, and fluid movement

- Evaluate and manage enhanced oil recovery

projects

·

Formation evaluation

- Determine reservoir porosity and fluid

saturations

- Pinpoint bypassed reserves

- Through-casing or drillpipe evaluation

- Production profile

- Determine borehole fluid holdup and

distribution, regardless of well deviation

- Evaluate injection or production profiles in

multiple string completions

·

Workover access and evaluation

- Identify bypassed hydrocarbons and establish

fluid contacts

- Slimhole access without compromising

measurement quality

- Evaluate stimulation operations

- Borehole diagnostics

- Identify casing leaks, water channeling, and

other behind pipe water flow

- Resolve completion problems

·

Pre-abandonment well evaluation

- Identify and assess commercial value of

bypassed hydrocarbons prior to well abandonment

- Locate trapped hydrocarbons between tubing

and casing strings for thorough environmental evaluation

Features

and Benefits

The RPM instrument can be run in

combination with the MCFM tool or with conventional production logging sensors

such as flow meters, temperature, fluid density, pressure, and hold-up

indicators. This combination flexibility

provides a complete multimode, multi-sensor solution-based system for a wide

range of downhole reservoir conditions and production environments.

The RPM

instrument is the industry’s most extensively characterized multimode tool,

with our unique dynamic response generator providing superior measurement

accuracy and confidence, independent of borehole geometry. Major advances in full 3-D and Monte Carlo

modeling provide a more accurate tool response characterization in a wide range

of borehole, casing, and formation/ fluid conditions.

Real-time

RPM data can be matched with previous generation PDK-100 results for easy

comparison in mature fields. For remedial work and time-lapse monitoring, RPM

data can be overlaid with existing logs in real time. An advanced feature of the RPM service allows real-time

computation of "intrinsic" ![]() . Innovative data analysis techniques provide

this sigma measurement corrected for borehole and diffusion effects without

prior knowledge of borehole size and fluid salinity. RPM corrected

. Innovative data analysis techniques provide

this sigma measurement corrected for borehole and diffusion effects without

prior knowledge of borehole size and fluid salinity. RPM corrected ![]() values

can be directly compared with borehole and diffusion corrected data from

PDK-100 or other PNC tools.

values

can be directly compared with borehole and diffusion corrected data from

PDK-100 or other PNC tools.

A History of Innovative Firsts in Pulsed Neutron Logging

Dresser Atlas, a predecessor of Baker Atlas, introduced the

first commercial pulsed neutron logging tool in 1963. The Neutron Lifetime Log® service

proved to be very successful for determining water saturation in

saltwater-bearing reservoirs.

In the

mid 1970s, Baker Atlas introduced the first

commercial Carbon/Oxygen log. The primary application of this

logging system was to determine water saturation in fresh, brackish, or mixed

salinity reservoirs.

Over the

next two decades, Baker Atlas introduced a second-generation pulsed neutron

log, the PDK-100 (1985),

the HydrologSM

(1989) and the Annular

Flow Log (1993). Another innovation, the Pulsed Neutron Holdup Imager, was

introduced in 1994.

In 1999,

Baker Atlas introduced the Reservoir

Performance Monitor (RPM) instrument, a multipurpose, pulsed neutron logging

tool. The new system

combines the measurement capabilities of all previous pulsed neutron devices

into one slimhole instrument, providing greater measurement flexibility than

ever before and setting the new standard for reservoir evaluation and analysis.

The POLARIS system, which incorporates the

Reservoir Performance Monitor (RPM) and Multi-Capacitance Flow Meter (MCFM),

was also introduced in 1999.

|

Application |

Operating Mode |

|

|

Formation evaluation (fluid saturations and porosity)

|

PNC, C/O |

|

|

Time-lapse fluid monitoring |

PNC, C/O |

|

|

Production/injection profiling |

PNC, C/O, PNHI, MCFM, AFL |

|

|

Evaluation of stimulation operation |

PNC, C/O, PNHI, MCFM, AFL, PRISM |

|

|

Hydrocarbon location in fresh, brackish, or unknown water

salinities |

C/O |

|

|

Bypassed hydrocarbon exploration in abandoned or workover wells |

PNC, C/O |

|

|

Production and reservoir depletion monitoring |

PNC, C/O, PNHI, MCFM |

|

|

Enhanced oil recovery project monitoring |

PNC, C/O |

|

|

Reservoir gas/oil/water contact monitoring |

PNC, C/O, PNHI, MCFM |

|

|

Future reservoir management base logs |

PNC, C/O |

|

|

Log-inject-log operations |

PNC, C/O |

|

|

Water channeling and/or casing leak identification Hydrolog |

AFL |

|

|

Water, oil, and gas holdups |

PNHI, MCFM |

|

|

Multiple string completion injection and production profiling |

AFL |

|

|

Hydrocarbon typing – differentiation between gas and oil |

PNC |

|

|

Locating trapped hydrocarbons between tubing and casing strings |

C/O, PNC |

|

Instrument Specifications |

||

|

Diameter |

1.6875 in. |

42.9 mm |

|

Length |

80 ft. |

24.4 m |

|

Weight |

375 lbm |

175 kgm |

|

Pressure Rating |

15,000 psi |

103 MPa |

|

Temperature Rating |

350° F |

177° C |

|

Min. Hole Size |

> 1.8 in. |

> 45.72 mm |

|

Operating Range |

3.7 - 9.0 in. |

94 - 229 mm |

|

Max bend radius |

30°/100 ft |

30°/30 m |

Multi-Capacitance

Flow Meter (MCFM)

System Overview

The

Multi-Capacitance Flow Meter (MCFM) is a multiple-sensor, production logging

instrument used to measure multiphase flow in highly deviated and horizontal

wells. The MCFM tool was jointly

developed by Baker Atlas and Shell International Exploration and Production

(SIEP) using technology developed by SIEP for monitoring multiphase flow in

surface flow lines.

The MCFM

deploys a wing containing 28 capacitance sensors that span the wellbore to

determine both flow composition (percentages of gas, oil, and water) and

velocity in order to measure flow rates (Qg , Qo , and Qw

).

The wing

section is dynamically oriented by the powered Positive Orientation Section

(POS) to ensure optimum vertical positioning, thus allowing the tool to

accurately measure three-phase flow, even in extremely high water cut

environments.

The wings of the MCFM tool are maintained in the

vertical position to measure multiphase flow behavior in horizontal wellbores.

A quartz pressure sensor is included in the MCFM

instrument to determine downhole pressures, and allow pressure surveys to be

carried out while an evaluation program continues, e.g., performing a shut-in

pressure survey.

|

Digital Sonan sensors also form an integral part of the MFCM diagnostic measurements, aiding in-flow regime identification and verification, channeling assessment, and flow behind pipe. Key Measurements

The

MCFM tool is a logging instrument capable of measuring all three phases –

oil, water, and gas – simultaneously. |

|

An across-the-wellbore velocity profile is

constructed from the transit-time measurements of the capacitance sensors in rows

one, two, seven, and eight of the MCFM tool.

Reservoir

Performance Monitor

System Overview

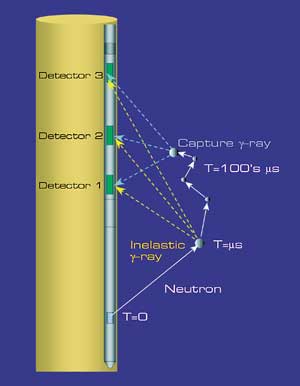

The RPM

instrument employs three high-resolution gamma-ray detectors arrayed above a

new, more efficient and reliable neutron generator. State-of-the-art detector electronics measure both the arrival

time and energy of detected gamma rays.

The generator is pulsed at distinct frequencies and the detectors

operate in various acquisition modes to obtain the different logging

measurements. The system is combinable

with other production logging instruments, and is constructed in short, modular

sections for ease in shipping and handling.

Operational Modes

Carbon/Oxygen spectroscopy mode –

principal measurement is the C/O ratio.

The neutron generator pulses at 10 kHz in the C/O acquisition mode with

the full inelastic and capture gamma ray energy spectra recorded by each

detector. These data are processed to

determine critical elemental ratios, including carbon/oxygen and calcium/silicon

from the inelastic spectra and silicon/calcium from the capture spectra. Data from each detector may be used

individually or in combination to provide optimal readings. C/O interpretation includes a new dynamic

response generator to accurately predict the expected C/O response level-by-level

in your well.

Pulsed Neutron Capture mode –

principle measurement is sigma, the thermal neutron absorption cross

section. In the PNC logging mode, the

neutron generator pulses at 1 kHz while the detectors record complete time

spectra, and an energy spectrum, used to monitor instrument stability. Time spectra from short-spaced and

long-spaced detectors can be processed individually to provide traditional

thermal neutron capture cross-sectional information. The two spectra can also be processed simultaneously to

automatically correct for borehole and diffusion effects and produce results

very near the intrinsic formation values.

RPM instrument principle of

operation- inelastic events; shown in yellow, occur during the generator

burst. Capture events, shown in blue,

occur after the neutrons become thermalized.

|

Instrument Specifications |

||

|

Diameter |

1.6875 in. |

42.9 mm |

|

Length |

29.9 ft |

9.12 m |

|

Weight |

115 lbm |

52.3 kgm |

|

Pressure rating |

20,000 psi |

138 MPa |

|

Temperature rating |

350° F |

177° C |

|

Minimum hole size |

> 1.8 in. |

> 45.72 mm |

|

Maximum bend radius |

30°/100 ft |

30°/30 m |

|

Pulsed Neutron Holdup Imaging mode measures

both sigma and the C/O ratio In

the PNHI acquisition mode, the neutron source pulse rate is also l kHz with

the measurements made to determine gas, oil, and water holdups. When combined

with other production logs, the PNHI can provide a comprehensive downhole

production profile picture, even in deviated or horizontal wells. Neutron activation mode measures

water flow oxygen activation The

neutron activation mode provides water flow measurements using one of several

data acquisition methods. Stationary measurements are made in either of two

operating modes. Measurements at selected logging speeds can be used to

segregate different flow rates in either an annulus or in an adjacent tubing

string. Precision Radioisotope Spectral

Measurements mode provides radioisotope identification and measurement With

the neutron generator turned off, the RPM tool can also be used to detect the

distribution of materials, tagged with radioactive tracers that are injected

into a well during stimulation treatments. In this logging mode, the

effectiveness of operations such as hydraulic fracturing or gravel pack

placement can be evaluated.

|

|

Cardinal Surveys Company

Odessa,

TX, Hobbs, NM

http://www.cardinalsurveys.com/default.asp

|

Positive monitoring of reservoir performance. |

|

|

|

Detailed, zone-by-zone, information. |

||

|

Changes in the downhole conditions detected. |

||

|

Reevaluate marginal production wells. |

||

|

Rework watered-out or gassed-out wells. |

||

|

Recompletion of unproductive offset wells. |

||

|

Guidance for remedial-workover designs. |

||

|

Cost-effective well recompletions. |

||

|

Improved completion for future wells. |

||

|

Immediate verification of perforation efficiency. |

||

|

Positive identification of the production intervals. |

||

|

Confirmation of openhole log analysis and assumptions

used in the initial completion. |

||

|

Pinpoint mechanical problems. |

||

|

Document baseline production profile for future

reference. |

||

|

Optimize pump placement. |

||

|

Discover unwanted water sources for remedial procedures.

|

||

|

Correlate production results with injection profiles for

sweep efficiency of floods. |

||

|

Confirm engineering and geological assumptions and

analysis. |

||

|

Verify stimulation job effectiveness and techniques. |

||

|

Plan accurate placement of mechanical isolation tools

(bridge plugs and packers.) |

||

|

Locate thief zones and undesirable cross-flows. |

||

|

Real-time snap shot of production well. |

Components

- Rope Socket (15" - 5/8" fishing

neck)

- Capacitance

Tool (40") – Functions as a capacitor. An insulated probe functions as one plate and the tool

housing acts as the other plate.

Various materials passing between the plates have different

dielectric properties that change the total capacitance of the

circuit. In most instances, a 3%

or more oil cut is necessary before a noticeable change in the capacitance

is registered. This 3% threshold

varies with the salinity of the water and the gravity of the oil. The primary advantage of the

capacitance tool over the older density tool is that its readings are not

dependent on a radioactive source and sensor. Thus, fluid identification cannot be affected by radioactive

material in the well bore or in the ejector. In addition, there is no long

half-life source of radioactive material to be fished should the tools be

dropped.

- Caliper

(7/8" O. D. [with arms retracted] by 68" in length and can be

used in hole up to 14 inches in diameter.

- Collar Locator (7/8” x 28.5") – magnetic

coil assembly

- Scintillation Gamma Ray Detector

(60"). It is a scintillation

type 9sodium iodide crystal).

- Microprocessor Controlled Ejector

(75.5"). The ejector is

digitally controlled. Its motorized plunger forces small bursts of

radioactive material out of a pressure chamber through an o-ring sealed

exhaust port on the side of the tool casing. The tool has the ability to consistently eject selected

slugs from 0.1 cc to a full 20 cc ejector dump.

- Temperature Tool (7/8" O. D. by 37"

in length). Accuracy approaches

0.1 degrees Fahrenheit. This

component is critical for channel detection. There is a platinum Resistor Temperature Detector

(RTD). A stable crystal oscillator

serves as an accurate, drift-free frequency reference in the tool electronics.

- Memory Pressure Gauge (14”)

- Total Tool Length with crossovers = 30’

General Guidelines

Avoid the intentional design of

tests that rely completely on nuclear-based data acquisition. Their maximum

radius of investigation is approximately 24 inches from the sensor.

‘Avoid the LAST LOG

SYNDROME. It is generally acceptable

for most production logs to be within 2 to 3 feet of measured depth. However, if you are on the 4th or 5th

generation of logs, you may be correlating 10’ to 15’ off depth. Always try to use the original open hole

logs or the logs used to perforate the well.”

Tracer Velocity

|

|

Pros:

Cons:

|

Generic Operations

- The

producing (pumping) temperature log is the first information available for

determining the status of this well's production and it can greatly

influence the strategy for investigating the well.

- A

correlation gamma ray survey and collar log is then run from T.D. up

through zones of interest. The

correlation log is compared to file logs to make adjustments to depth.

- A

capacitance log is then run from T.D. to above the pump. The capacitance tool can differentiate

between water, oil, and gas in the well bore. Note that when calibrated, pure water is one extreme, pure

air or gas the other, and pure oil is about a 75% reading.

- The

next step is to run the radioactive tracer survey. The tracer will allow the determination

of the direction and rate of fluid movement. There are the three basic

components of the tracer: 100% shot, zone breakdown shots, and no-flow

shots. The 100% shot is ejected

above the top perforation. As the single radioactive slug travels up the

wellbore, at least three passes through the slug are recorded. By measuring the distance of movement

and the time of travel, it is possible to calculate the velocity and

therefore, the volumetric flow rate in the casing. This method of velocity measurement is

necessary because of pump surges in the fluid column. Stationary velocity readings are not

accurate. Zone-by-zone breakdown

is accomplished by the same velocity method as the 100% slug. Readings are taken in areas between

sets of perforations. Each set of

rates obtained is compared back to the 100% shot and a percentage of entry

is calculated for each set of perforations. A no-flow shot is ejected between the bottom perforation and

LTD. It is monitored in the same manner as the other velocity

measurements. The primary

objective is to determine if there is any fluid movement from below LTD in

the casing. This is essential

information. If the temperature

surveys indicate fluid movement from below LTD, the no-flow shot is the

only means to prove whether the movement is inside or outside the casing.

- The

log may or may not be complete at this point. After determining the type and quantity of fluid being

produced from each zone, decay temperatures and cross flow surveys may be

needed for further definition. It is almost always a good idea to run at

least one decay temperature survey unless all objectives for running the

survey have already been conclusively reached through the prior survey

methods.

GAMMA-TROL (Stimulation Evaluation Logging)

Combined with a radioactive tag, stimulation evaluation

logging assists in inferring treatment placement. Included in the service is either a temperature or gamma-ray log

or both. Cardinal Surveys Company

offers these services either separately or combined under the following names:

- Gamma-Trol

(Gamma-ray only)

- Temp-Trol

(Temperature only)

- Gamma-Trol

II (Combination

- Gamma

ray and Temperature).

The Gamma-Trol II service can

also be used to locate the top of cemented intervals. The cement can be tagged

during cementing, and the temperature and gamma ray log will accurately

pinpoint the cement top.

Injection Profile (Radioactive Tracer Profile Logging)

An accurate profile of the exact placement of injected

fluids is essential for proper management of water injection. The Injection Profile Log, usually

consisting of a temperature log, two radioactive tracer logs (the intensity

profile and a series of stationary velocity measurements), channel checks,

packer checks, injecting temperature log, shut-in temperature logs and

cross-flow checks (where applicable), can be used for getting profiles.

This log is used to determine the placement of injection

fluids in the formation. Of general

interest is a profile of the zone-by-zone placement of injected fluids versus

rate. A comparison of injection and

shut-in temperatures can be used to qualitatively determine major storage

(injected) zones.

In tertiary or Enhanced Oil Recovery (EOR) projects, the

injection profile is applied in a similar manner. Sometimes special logging techniques are required due to the

physical properties of the injection fluids.

Many tertiary or EOR projects alternate injection of multiple fluids

(Water After Gas-WAG, or vertical profile modifications such as polymer treatments). In these instances, it may be desirable to

log the well after each change in injection fluid to determine the relative

impact of different fluids.

Because a radioactive tracer is used, the Injection

Profile also affords other benefits such as location of casing annulus

channels. Channels in the casing

annulus can be seen when tagged fluid exits the casing through a perforation

and continues in a path near the wellbore.

The extent of the channel can be determined by following the tagged

fluid as long as it remains near the wellbore.

In a similar manner, communication between perforated intervals can be

discovered. The radioactive tracer

identifies other mechanical problems such as holes in the casing, unopened

perforations, leaking packers or bridge plugs.

“Due to the versatility of the radioactive tracer, it is

the best and most accurate method of running a Mechanical Integrity Test (MIT)

on disposal wells.” Using the same

logging procedures, the radioactive tracer can yield the zone-by-zone breakdown

of fluids exiting the wellbore.

Temperatures can also aid in identifying any upward or downward

channels.

TRAC-III

Production Logging

Cardinal's TRAC-III logging

string consists of a Scintillation Gamma Ray Detector,

(microprocessor-controlled) Radioactive Ejector, Collar Locator, Capacitance

Probe, Caliper, and Temperature Tool.

All sensors come in 7/8"

O.D., 1" O.D., 11/4"

O.D., and 13/8" O.D. cases. The tools are used to:

·

Document baseline production profile for future

references.

·

Verify effectiveness of well treatments.

·

Discover unwanted water sources for remedial procedures.

·

Correlate production results with injection profiles for

sweep efficiency of floods.

Well Parameters For Example

Procedure

|

Production |

20 BPD Oil |

210 BPD Water |

100 MCFD Gas |

|

Surface Pressure |

<300 PSI |

Casing |

5.5" |

|

Tubing |

2.875" |

Packer |

5500' |

|

Perforations |

5600' - 6000' |

PBTD |

6100' |

The following procedure

represents the fundamental steps needed to accomplish most TRAC-III

applications. However, due to the

investigative nature of production logging, it must be noted that the following

procedure may be modified at any point in order to optimize the definition of

events or abnormalities. This procedure should be considered as a general plan

of action.

1. Conduct

safety meeting to identify location hazards, review well information, review

test objectives, and make necessary plans to maximize safety and test results.

2. Rig up

Cardinal Surveys logging unit and conduct the pre-job wellhead radiation

survey.

3. Attach

Cardinal Surveys 1 3/8"

O. D. TRAC-III tool string which consists of a Rope Socket (1.375" x

15" with a 5/8" fishing neck), Capacitance Tool (1.375" x

40"), Caliper (1.375" x 69"), Collar Locator (1.375" x

28.5"), Scintillation Gamma ray Detector (1.375" x 60"),

Microprocessor Controlled Ejector (1.375" x 75.5") with I-131 as the

tracer isotope, and a Temperature Tool (1.375" x 37").

4. Install

5,000 psi lubricator and test for leaks.

5. Pressure

up lubricator and secure wellhead.

6. RIH with

TRAC-III tool string into the tubing.

7. Run Flowing

Temperature and CCL Logs from 5,400 to 6,100.

8. Run

Gamma ray and CCL logs from 6,100 to 5,400. Correlate Gamma ray and CCL logs to

supplied correlation log. Adjust depth measurement from Wireline Depth to

Measured Depth.

9. Return

TRAC-III logging string to T.D. at 6,100 and run Capacitance Log from 6,100 to

5,400.

10.

Return TRAC-III logging string to T.D. at 6,100 and run

Caliper from 6,100 to 5,400.

11.

Place TRAC-III logging string above the zone of interest

5600 - 6000 and eject a slug of radioactive material. As the slug travels up hole with the flow, make at least 3 passes

through the material with the recorder set to depth drive. Note the delta times from peak to peak. This

will allow for a 100% velocity reading.

12.

Repeat step 11 two more times.

13.

Repeat step 11 in areas between perforated intervals or

between areas of interest in the openhole section. Refer to the caliper results from 5600 - 6000 when placing the

radioactive slugs. Try to avoid areas

of drastic I.D. change to minimize the error in the velocity measurements.

14.

Eject a slug of radioactive material below the zone 5600 -

6000 and above T.D. at 6,100. Eject the

slug as low as possible if there is no rathole. Make several passes through the material to determine if there is

any flow coming from below T.D. in the wellbore.

15.

Shut-in production at wing valve.

16.

Allow the well to remain static for approximately one

hour.

17.

Run a Shut-In Temperature Log from 5,400 to 6,100.

18.

Perform crossflow checks.

Shoot a series of radioactive slugs approximately 50 feet apart across

the zone 5600 - 6000 and make timed passes through all of the slugs at the same

time to determine if there is any crossflow between zones.

19.

Run a Shut-In Temperature Log from 5,400 to 6,100 approximately

2 hours after the well has been shut-in.

20.

It may be desirable to pull a Shut-In Capacitance Log at

this point from 6,100 to 5,400.

21.

POOH with Cardinal Survey's TRAC-III production logging

tool string.

22.

Rig down equipment, return well to prior status, and

conduct the post job wellhead radiation survey.

Stabilization

Stable

producing conditions are crucial to running a TRAC-III that will give insight

to the wells normal production characteristics. This is important when the test objective is to see the well's

production profile. It is also important for determining the effects of a past

stimulation that is not performing as expected.

If we

run a TRAC-III immediately after the well has been worked over, it will only

tell us what the well does at that particular point in time. You want to allow the production to

stabilize, unless you have had a sudden, large increase in water production.

It does not matter if this increase of water production was

brought on by a stimulation, direct channel from an offset injector, or natural

causes. Don't wait for

stabilization. There is a strong

possibility this new water is from a higher pressure source than anything

you've been producing. In these

situations there is regularly crossflow into proven oil zones. It is necessary to find the water source so

that you can take remedial action.

GAMMA

TROL

GAMMA TROL - II is a combination

of Temperature and Gamma Ray logging used determine the placement of well

stimulations and treatments.

Well Parameters For Example Procedure

|

Frac |

140,000 lbm 20/40 |

BHT |

90oF |

|

Surface Pressure |

<3,000 psi |

Casing |

5.5" |

|

Tubing |

2.875" |

PKR |

5600' |

|

Perforations |

5700' - 6000' |

PBTD |

6100' |

The following procedure

represents the fundamental steps needed to accomplish most GAMMA TROL ®

applications. However, due to the

investigative nature of production logging, it must be noted that the following

procedure may be modified at any point in order to optimize the definition of

events or abnormalities. This procedure should be considered as a general plan

of action.

1. Conduct

safety meeting to identify location hazards, review well information, review

test objectives, and make necessary plans to maximize safety and test results.

2. Rig up

logging unit on and conduct the pre-job wellhead radiation survey.

3. Attach

Cardinal Surveys GAMMA TROL ® tool string which consists of a Rope Socket

(1.25" x 15" with a 5/8" fishing neck), one or more weight bars,

Collar Locator (1.375" x 28.5"), Scintillation Gamma ray Detector

(1.375" x 60"), and a Temperature Tool (1.375" x 37").

4. Install

wireline blow out preventer and tool trap.

5. Install

lubricator and test for leaks.

6. RIH with

GAMMA TROL ® tool string into the tubing.

7. Run Base

Temperature and CCL Logs from 5,500 to 6,100.

8. Run

Gamma Ray and CCL logs from 6,100 to 5,500.

Correlate Gamma ray and CCL logs to supplied correlation log. Adjust

depth measurement from Wireline Depth to Measured Depth.

9. POOH

with Cardinal Survey's GAMMA TROL ® production logging tool string.

10.

Rig down equipment, store lubricator in a safe area, and

stand by during well stimulation.

11.

Record ISIP and 15 minute shut-in pressures.

12.

Install wireline blow out preventer and tool trap.

13.

Install lubricator and test for leaks.

14.

RIH with GAMMA TROL ® tool string into the tubing.

15.

Run After Temperature and CCL Logs from 5,500 to 6,100.

16.

Run After Gamma ray and CCL Logs from 6,100 to 5,500.

17.

Allow well to remain static for approximately one hour.

18.

Run a Shut-in Temperature Log from 5,500 to 6,100.

19.

POOH with Cardinal Survey's GAMMA TROL ® production

logging tool string.

20.

Rig down equipment and conduct the post job wellhead

radiation survey.

Radioactive

Tagging

The Tagmaster ® was developed in

the late 1970's.

Downstream, High Pressure Tagging

Tagging

a treatment downstream of the pumps has many inherent advantages over injecting

radioactive material in the low-pressure pump intakes.

·

No

surface equipment (pumps, blender, manifold, etc.) has radioactive material

passing through it. This prevents a

buildup of contamination that will accumulate to a point where field personnel

will be exposed, not only to the radiation passing through the system, but also

to residual contamination from past tags.

These units can become too contaminated to be legally operated!

- The radioactive flush is instantaneous. There is no opportunity for any

particles to become trapped in surface equipment that might be released

during flush.

- If a frac treatment screens out to the

surface, all contamination will be downstream from the "T"

assembly.

- If there is a radioactive spill, it will be in

an area with no personnel in the immediate vicinity.

- Personnel exposure is kept to a minimum.

Placement

of Radioactive Storage

While

chronic exposure to low level radiation is hazardous, the immediate danger is

from exposure to the radioactive additive in concentration. Many systems store the radioactive additive

on, or near, charged fluid lines. If

the line should burst you could have a dangerous and expensive problem to

contend with. The Tagmaster ® stores

radioactive material in concentration 50 - 100 feet away from all treating

lines.

Storage

Containment

pots for the radioactive additive are mounted in the back-center of the

Tagmaster®. The pots are plastic

coated, steel containers that have approximately one inch of lead

shielding. This gives five half-value

layer shields for Iridium 192, the primary isotope used in the Tagmaster ®.

Professional

Tagging Technicians

All of Cardinal's technicians

have received government approved training programs. They are trained in the proper methods of containment, cleanup, A.L.A.R.A. techniques,

Cardinal's regulations, and government regulations concerning the

transportation, use, and exposure limits of radioactive materials.

Tagmaster

® Quality Control Log

The

Tagmaster ® Quality Control Log is an optional service offered by Cardinal

Surveys Company. It entails a PC based

data acquisition system that monitors radiation intensity of injected materials

during the stimulation.

RSO

Cardinal's Radiation Safety

Officer is responsible for safety, training, and regulatory compliance where

radioactive materials are involved. The

RSO maintains and reviews records of Before and After Location Surveys,

Personnel Exposure (whole body and thyroid bioassay), and monitors Cardinal

facilities.

He also holds a prominent

position in the Radiation Safety Committee. Records and procedures are

periodically reviewed by the committee to make changes where needed to enhance

our A.L.A.R.A.

program.

Isotope

Quality Control

Cardinal

has the majority of isotopes we use in the Tagmaster ® targeted by the Nuclear

Science Center at Texas A&M University.

Our control of materials supplied for targeting and follow-up testing,

with a state of the art 4096 channel spectrum analyzer, assures quality and

quantity control.

Tagmaster

® Specifications

·

4140 Carbon Steal "T"

·

Weco 1502 connections

·

20,000 psi working pressure valve

·

20,000 psi working pressure check valve

·

14,000 psi working pressure hose with 40,000 psi minimum

burst pressure

·

20,000 psi working pressure manifold

·

4 - Plastic coated, steal containment pots with 1" of

lead shielding

|

Isotope |

Atomic

Symbol |

Half-Life |

Special

Concerns |

Photo

peaks Mev |

|

Iodine |

131I |

8.04 days |

Thyroid Seeker |

9.99 (X-ray), 0.08, 0.2843, 0.3645, 0.638, 0.724 |

|

Iridium |

192IR |

74.2 days |

None |

0.067 (X-ray), 0.140 (Compton), 0.210 (Compton), 0.315,

0.470, 0.605, 0.79, 0.90 (shoulder) |

|

Scandium |

46SC |

83.8 days |

High Beta/Energy |

0.887, 1.119, (0.89 plus 1.1 sum peak) |

|

Antimony |

124SB |

60.2 days |

High Beta |

0.603, 0.645 (hidden shoulder), 0.722 (shoulder peak),

1.30 - 1.37, 1.69, 2.09, (1.69 plus 0.603 sum peak) |

|

Gold |

198AU |

2.696 days |

High Beta |

0.412 |

|

Bromine |

82BR |

35.34 hours |

High Energy |

0.55, 0.61, 0.7, 0.77, 1.04, 1.33, 1.48, 1.90, 2.14 |

Expro RAM Production Logging Tool

Expro

International Group PLC 2001

Expro North Sea Ltd

Kirkhill Place

Kirkhill Industrial Estate

Dyce

Aberdeen

AB21 0GU

Tel: +44 1224 214600

Fax: +44 1224 770295

http://www.exprogroup.com/casedholeservices/epl.htm

Introduction

In

1986, Expro performed the first memory PLT operations in the UK North Sea. Additional development led to the release of

the Expro RAM production logging tools in 1998.

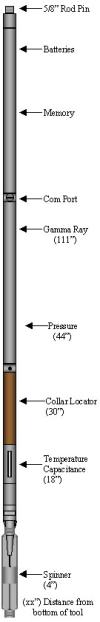

The five main sensors - Gamma Ray, Collar Locator,

Quartz Pressure, High Resolution Temperature and Fluid Capacitance - are

contained in one assembly measuring only 55 inches (1.4 meters) long. This construction removes 8 electronic

pressure sealed connectors from the string therefore lessening the chance of

connector failure and improving overall reliability. The RAM tool is combinable with up to 9 additional sensors such

as calipers, fluid densities and extra spinners. However, in its normal deployment mode, with one spinner, the

total PLT length is 112 inches (2.85 meters) for surface readout and 138 inches

(3.5 meters) for memory applications.

Offshore, this compactness

allows deployment of PLT operations in the most restricted of areas and on land

eliminates the requirement of having large deployment cranes on site. It also means that the tool does not need to

be fully disassembled between jobs thereby reducing rig up and rig down time.

Applications

The RAM tool is a short,

all-in-one production logging tool, providing flow, quartz pressure,

temperature, fluid dielectric, gamma ray and CCL. Use of a single combination tool increases reliability by

minimizing electrical and mechanical connections, reduces rig up time, improves

data quality through the close proximity of all sensors and brings the benefits

of a smaller toolstring - allowing well access from even the most restricted of

areas.

In addition, the tool has the

ability to deploy 100% downhole backup while remaining shorter than most other

single toolstrings. A separate

telemetry cartridge connects to the upper head and is available in a number of

telemetry formats. A High Speed

Telemetry Cartridge (HSTI) or High Speed Memory Interface (HSMI) Cartridge can

be attached to the upper head. The RAM

is both memory and SRO compatible, requiring no separate interfaces or modules.

A range of industry-standard

sensors can be connected to the tool’s lower head - such as fluid density,

accelerometer, x-y-calipers, fluid profile, inline flowmeter or continuous

flowmeter. The high temperature and

pressure rating make the RAM tool suitable for a wide range of production

logging operations and its use results in a typical full-length string of only

112”/2.9m.

All tools are manufactured in

NACE specification (MR0175) materials for use in wells containing H2S/CO2

Flowmeter

Range

(Interface)........................................................ 30

- 60,000 bbls/day

Directional.............................................................................................. Yes

Resolution............................................................................. 12

pulses/rev.

Pressure

Type................................................................................................. Quartz

Range...................................................................... 15,000

psi - 16,000 psi

Accuracy...................................................................................... 0.02%

FS

Resolution.................................................................................. <0.008

psi

Repeatability................................................................................ 0.01%

FS

Temperature

Range............................................................................... 0

- 177°C/350°F

Accuracy..................................................................................... 0.5°C/1°F

Resolution.......................................................................... 0.025°C/0.05°F

Time

Constant............................................................................... <1.5

sec

Gamma

Ray

Range..................................................................................... 0

- 1,000 API

Sensitivity................................................................................. 1

Count/API

Fluid

Dielectric

Range............................................................................................ 0

- 40%

Accuracy..................................................................................... 2%

Range

Resolution........................................................................................... 0.1%

RAM Specification

Diameter |

13/8”

(35mm) |

111/16”

(43mm) |

|

Length |

55” (1.4m) |

55” (1.4m) |

|

Pressure (max) |

15,000 psi |

20,000 psi |

|

Temperature (max) |

177°C (350°F) |

177°C (350°F) |

|

Weight in air |

35 lbs (16 kg) |

52 lbs (23.6 kg) |

|

Fishing Strength |

10,000 lbs (4,550 kg) |

10,000 lbs (4,550 kg) |

|

Sensor Supply Voltage |

12v |

12v |

|

Line Voltage (SRO) |

60 - 250v |

60 - 250v |

|

Current |

80mA |

80mA |

Multi Sensor

Memory Production Logging Tool

The tool is able to operate in deviated or

horizontal wells and has the capability to log all types of multiphase flow and

can be deployed via slickline, coiled tubing or e-line. All of the MS-MPLT sensors are compatible

with the Expro RAM PL tools.

Applications

- Vertical,

deviated or horizontal wells

- Determination

of downhole flow rates

- Layering

- Zonal

distribution

- Crossflow

and leaks

- Multi-phase

flow

Technical

Specification

Memory |

|

|

Type |

Non-volatile EEPROM |

|

Size |

Expandable up to 16Mb |

|

Sample rate |

Multiples of 0.1 sec |

|

Data set |

Minimum of 30,000 on all channels |

|

Length / OD |

2ft / 111/16" (0.61m / 43cm) |

Full-bore Flowmeter |

|

|

Size |

Various for use in up to 95/8" casing |

|

Measurement range |

100 to over 30,000 bbl/day in 7" casing |

|

Length / OD |

2.95ft / 111/16" (0.89m / 43cm) |

In-line Flowmeter |

|

|

Size |

21/8" and 111/16" |

|

Measurement range |

600 to over 60,000 bbl/day |

|

Length / OD |

1.44ft / 111/16" (0.43m / 43cm) |

CCL |

|

|

Type |

Passive |

|

Length / OD |

1.53ft / 111/16" (0.46m /

43cm) |

Gamma Ray |

|

|

Type |

Scintillation |

|

Sensitivity |

1 cps / API unit |

|

Length / OD |

2.2ft / 111/16 (0.67m / 43cm) |

Water Hold-up |

|

|

Type |

Capacitance |

|

Measurement range |

0.01 to 1 (accuracy decrease at high values) |

|

Length / OD |

2.18ft / 111/16" (0.66m / 43cm) |

Pressure |

|

|

Type |

Shear quartz |

|

Accuracy |

± 3.2 psi (± 0.22 bar) |

|

Repeatability |

± 0.005% of full scale |

|

Length / OD |

1.02ft / 111/16" (0.29m / 43cm) |

High Resolution Temperature |

|

|

Type |

Platinum resistance |

|

Accuracy |

± 0.5ºC |

|

Resolution |

0.09ºC |

|

Length / OD |

1.02ft / 111/16" (0.29m /

43cm) |

|

All sensors are rated to 150ºC |

|

Radio Active Fluid Density |

|

|

Type |

Radio active source |

|

Length / OD |

2.18ft / 111/16" (0.66 /

43cm) |

X-Y Caliper |

|

|

Type |

4 arm |

|

Length / OD |

3.25ft / 111/16" (1m / 43cm) |

Halliburton

http://www.halliburton.com/spe98/flow2000.asp

Flow 2000 Production Logging

Services

In addition to the high-speed telemetry/gamma ray/casing collar locator cartridge, the Flow 2000 production logging stack includes the following sensors:

|

·

HMR Gauge Carrier

provides fast, high-resolution transient well testing with pressure

derivative in real time. ·

Capacitance Holdup Tool

identifies three-phase flow with low water cuts. ·

Gas Holdup Tool provides fullbore gas

holdup from low energy gamma ray scattering in fluid and steel pipe. ·

Differential Pressure Tool

determines liquid holdup and identifies fluid in wellbore deviations up to

70°. ·

Six-Arm Fullbore Spinner

measures mono- and multi-phase flow with a threshold above 100 BFPD (in 7-in.

casing). ·

Enhanced Flow Diverter for

multiphase production or injection flow rate measurements and enhanced

multi-layer transient testing. ·

Enhanced Wheeled Centralizer

provides strong centralization in vertical, deviated, and horizontal wells. |

|

http://www.kusterco.com/kplt.htm

Kuster Production Logging Tool

(KPLT)

|

|

Input Power: |

Data Sampling: |

|

Analog Sensor Interface: |

Digital Sensor Interface: |

|

|

Memory Capacity: |

Sensor Specifications: |

|

|

Pressure: |

Flowmeter Sensor:(Full Bore and Continuous) |

|

|

Dielectric Sensor: |

Gamma Ray: |

|

|

Casing Collar Locator: |

Sensor Descriptions: |

Memory

Section - Serves as the programmable central processing unit,

which has been programmed to interrogate and record to memory measured sensor

data at a prescribed sampling rate.

Temperature -

Measure the temperature of the wellbore fluids to delineate fluid entry or exit

and production/injection history.

Dielectric -

Measures the capacitance of the wellbore fluids to delineate the mixture of

water and hydrocarbons.

Gamma

Ray - Measures gamma ray emissions from the downhole

environment and is used as a "depth-control" tie-in to openhole logs.

Casing

Collar Locator - Measures locations of tubing and casing collars for

depth control.

Pressure -

Measures pressure of wellbore fluids for use in PVT calculations and

calculation of gradients for fluid identification.

Full

Bore Flowmeter - Measures the change in fluid velocities and

incorporates into bulk flow to provide injection or production profile (for

casing diameters).

Continuous Flowmeter -

Measures the change in fluid velocities for single phase and small diameter

pipe.

High Temperature Production

Logging Tool

Lee Tool Division of Schlumberger Canada Ltd.

7449 - 49Avenue Crescent

Red Deer, Alberta

T4P 1X6

Phone: 403.347.2524

Fax: 403.342.5065

http://www.leetool.ab.ca

Memory Production

Logging System

The Lee Tool Memory Production

Logging System is a cost-effective, rugged, and easy to use PC-based system and

tool string.

Memory Logging is the

measurement of a wellbore environment where tool power and data storage are

incorporated within the logging tool, thus eliminating the need for electrical,

radio frequency, or fluid continuity to surface. The Memory Production Logging (MPL) system consists of two groups

of components: the surface system and the downhole tools. These two portions of the system operate

independently of each other. They are

only linked together when the tool is being programmed or when the data from

the tool is being downloaded.

Surface System

Downhole Tools

Tool Sensors may include a combination of the following:

- PC Computer (PC-Logger) Battery Section

- Remote Speed/Depth Display Memory Production

Logging Adapter

- Tool Interface Box Tool Sensors (see below)

- Thermal Continuous Feed Plotter

- Depth Encoder

- CCL Nuclear Fluid Density Thermal/Epithermal

Neutron

- Gamma Ray Flowmeter XY Caliper

- Dielectric Pressure Multi-finger Caliper

- Gradiomanometer Temperature

Deployment Methods

- Drillpipe/tubing conveyed logging, both

vertical and horizontal

- Coiled tubing conveyed logging, both vertical

and horizontal

- Slickline conveyed logging

- Long-term logging set in a landing nipple

- Used in conjunction with electric line - cased

or open hole tools

Applications

- Flow Profile/Injection Profile Logging

- Depth Correlation

- Extended Flow, Pressure and Temperature Tests

- Transient Rate and Pressure Tests

- Mechanical/Hydraulic Isolation Logging

- Lost Circulation Zone Detection

- Neutron Logging

- X-Y Open Hole/Casing Caliper Log

- Multi-Finger Tubing Caliper

- Cement Top and Cement Plug Logging

- Casing/Tubing Leak Detection

- Collar

Locator

- Gamma

Ray

- Gradiomanometer

- Centralizer

- Dielectric

- Pressure/Temperature

- Fullbore

Flowmeter

- Memory

Adapter

- Spinner

The surface depth files are

merged with the downhole data with time as the common link. The data are then presented in standard log

format for all sensors and passes. Line

speed, depth and spinner RPS are used to create a calibration file or spinner

crossplot. This spinner crossplot is

then included with overlays to provide a wellsite interpretation/presentation.

Time Synchronized

Before beginning the job, the

MPL adapter is connected to the PC-Logger computer. Both have internal real time clocks that are now synchronized. When the job commences, the MPL adapter

records data vs. time, while the PC-Logger computer records depth vs. time

After the job is completed, the

MPL adapter is connected to the PC-Logger computer. The depth vs. time files from the PC-Logger computer are merged

with the data vs. time memory from the MPL adapter. Time is used as the reference and the resulting files contain

data vs. depth. These files are now standard log output, the same files that

would be generated by real time logging.

Tool Sensors

The PC-Logger is a stand-alone

PC system, built to withstand field use, yet portable and easily transported by

boat or helicopter to remote locations.

The surface PC-Logger acquisition system is common to both real time and

memory. To go ROM memory to real time,

simply replace the downhole MPL adapter with a telemetry section and add a

power supply at surface. This will

provide full real time capabilities for all standard Production Logging

Services on mono conductor cable.

MPL adapter electronics contain

32 megabytes of Flash EPROM memory with an open architecture design that

supports future memory expansion. The

MPL Adapter is the memory-logging equivalent to Surface Readout (SRO)

telemetry. The MPL Adapter counts the pulses from each sensor, sorts records

and compresses the data within its own memory for retrieval at surface.

A variety of tool sensors are

available, in 1-3/8" (34.99mm) or 1-11/16" (42.9mm) strings, capable

of working up to 10,000 psi (70 MPa) and 302 degrees Fahrenheit (150 degrees

Celsius).

Madden Systems Incorporated

Madden Systems Incorporated

1801 E. Pearl Street

Odessa, Texas 79761

http://www.maddensystems.com/index.htm

Production Logging

Introduction

Production logs are used to determine dynamic and static downhole conditions in production, injection, and disposal wells.

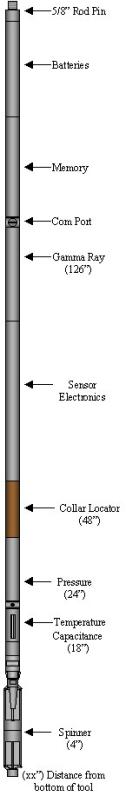

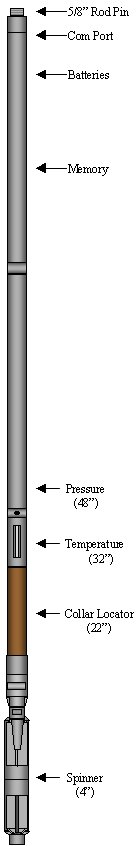

Standard Production Logging Tool (280oF

Rating)

|

|

This

Slicklogger® System's physical characteristics of a short, rigid, single

housing and small O. D. make it a durable solution for coiled tubing

applications in highly deviated well bores. The system also excels in getting

by tight radius crooks in vertical well bores This tool can be run in a

memory or electric line configuration. |

Tool Specifications

|

Tool Length Memory Configuration 15'

9" E-Line Configuration 10'

9" Tool O.D. 1.375" Pressure Sensor Type: Quartz Crystal Accuracy: ± 0.03% F.S. Resolution: 0.01 psi Ranges: 10k, 16k, 20k Make: Quartzdine Temperature (Borehole) Rating: 280 degrees F Type: Platinum RTD Accuracy: ± 1 Deg. C. Resolution: 0.001 Deg. C. Response: 0 - 100 Deg. C (4

seconds) Temperature (Compensation) Accuracy: ± 1 Deg. C. Resolution: 0.01 Deg. C. Gamma Ray Detector Type: Scintillation Collar Locator Type: Coil / Rare Earth Magnet

Capacitance (Fluid I.D.) Determine water presence in

well bore fluids. Flow Meter (Spinner) Type: Continuous Sensors: Reed Switch /

Magnetic Resolution: 0.25 rps or 0.08

rps Data Status: Velocity /

Direction / Diagnostics Output Logging Curves Gamma Ray |

|

Hazardous Conditions Production Logging Tool (450oF Rating)

The tool

has a small O. D. of 1 5/8". This

tool has metal seals in addition to o-rings and is capable of operating in very

hot and corrosive environments. It has successfully run on 25,000 feet of 7/32”

electric line to depths in excess of 18,000 feet and temperatures over 500oF.

This tool can be

run in a memory or electric line configuration.

|

Tool Length Memory Configuration 18'

3" E-Line Configuration 10'

5" Tool O.D. 1.625" Pressure Sensor Type: Quartz Crystal Accuracy: ± 0.03% F.S. Resolution: 0.01 psi Ranges: 10k, 16k, 20k Make: Quartzdine Temperature (Borehole) Rating: 450 degrees F Type: Platinum RTD Accuracy: ± 1 Deg. C. Resolution: 0.001 Deg. C. Response: 0 - 100 Deg. C (4

seconds) Temperature (Compensation) Accuracy: ± 1 Deg. C. Resolution: 0.01 Deg. C. Gamma Ray Detector Type: Scintillation Collar Locator Type: Coil / Rare Earth Magnet

Capacitance (Fluid I.D.) Determine water presence in

well bore fluids. Flow Meter (Spinner) Type: Continuous Sensors: Reed Switch /

Magnetic Resolution: 0.25 rps or 0.08

rps Data Status: Velocity /

Direction / Diagnostics Output Logging Curves Gamma Ray |

|

Onboard

diagnostics record systems failures to allow compensation of data while logging

at these extremely high temperatures.

This gives a quality control base to cross reference-acquired data to

downhole events, rather than possible tool problems.

Geothermal Production Logging Tool

This

tool was developed for the Geothermal Industry and Scientific Community to

allow surveillance of steam wells used in the generation of electricity. We have successfully logged wells with a

bottomhole temperature of over 650oF.

The Geothermal Tool contains all the sensors our

other Slicklogger® systems do with the exception of a capacitance (dielectric)

probe. However, it is rarely needed in applications at its designed temperature

range. The Delta Pressure calculations

suffice for fluid identification in that realm.

While the tool has the capability to be run as a

memory tool, it is most often used with e-line in a surface readout

configuration.

|

Tool Length Memory Configuration 16'

4" E-Line Configuration 10'

5" Tool O.D. 1.77" Pressure Sensor Type: Quartz Crystal Accuracy: ± 0.03% F.S. Resolution: 0.01 psi Ranges: 10k, 16k, 20k Make: Quartzdine Temperature (Borehole) Rating: 650 degrees F Type: Platinum RTD Accuracy: ± 1 Deg. C. Resolution: 0.001 Deg. C. Response: 0 - 100 Deg. C (4

seconds) Temperature (Compensation) Accuracy: ± 1 Deg. C. Resolution: 0.01 Deg. C. Optional Gamma Ray Detector Type: Scintillation Collar Locator Type: Coil / Rare Earth Magnet

Flow Meter (Spinner) Type: Continuous Sensors: Reed Switch /

Magnetic Resolution: 0.25 rps or 0.08

rps Data Status: Velocity /

Direction / Diagnostics Output Logging Curves Gamma Ray Onboard diagnostics record

systems failures to allow compensation of data while logging at these

extremely high temperatures. This gives us a quality control base to cross reference-acquired

data to downhole events, rather than possible tool problems. |

|

The Purpose of Production Logging

A

typical assumption that may be made is that production is coming only from the

perforated zone. It is not uncommon to

find production communicating behind the pipe from a supposedly "isolated

zone" and entering the wellbore at the perforated interval. Many times, the perforated interval will be

depleted and accepting crossflow from the "isolated zone". This production may, or may not be lost due

to economic restraints and it will certainly cause a conflict in the reserve

calculations for the two zones. Future

completions could also be jeopardized by this unintentional and uncontrolled

depletion.

Case in

point:

A

customer called wanting to know his options for determining where a foamed

cement or polymer squeeze would go to if he pumped one in his well. The field had a history of a bottom water

drive encroaching up to the productive pay and he was concerned how much damage

the partially depleted zone would incur during a squeeze job. His concern was justified in that this well

was the best producer in the field and several of his past treatments were

failures. The wells made more water and

less hydrocarbons after the treatments.

It was suggested

that he use a production log to identify the problem and then design a

conformance treatment for that particular problem. The production log indicated

that the water source was not from below as anticipated, but from 400' above

the primary pay. The water source was also crossflowing into the primary pay.

The solution was as simple as a few perforations and an old fashioned

"Bullhead Squeeze". Relatively low tech and low cost, but an adequate

solution.

What if:

Where

do you think the polymer or foamed cement treatment would have gone had the job

been run on the assumption? It would

have gone to the lowest pressured interval in the well, which is the primary

pay.

Principles

Of Operation - Sensor Measurement

Frequency Measurement

The

instrument - using a standard time-period-averaging technique, measures time

period, rather than frequency. The

sensor signal is used to gate a high frequency (8 MHz) reference clock, which

effectively times a known number of sensor signal cycles.

At

calibration time, the minimum possible frequency over the working temperature

and sensor range is determined, and used to calculate how many sensor signal

cycles can be counted in a given measurement time. We presently calculate this figure for 1, 2, and 3 seconds, and

the instrument dynamically decides which figure to use depending on the

sampling rate selected by the operator.

Thus, a sampling rate of 3 seconds will have better resolution than a 1

second rate. Again this is dynamic and

during the job the resolution will change depending on the sample rate at a

given time.

Example Pressure Resolution Calculation

Given a

one second sampling interval, with some overhead time for data transmission and

other measurements approximately 650 ms is available for pressure frequency

measurement. At a minimum pressure

crystal frequency of 23 kHz, the number of cycles occurring in 650 ms is 23000

x 0.650 = 14950.

The tool

will therefore count 14,950 pressure signal cycles and use the 8 MHz reference

clock to measure elapsed time, to the nearest eight-millionth of a second. At minimum pressure, therefore, the number

of reference clock cycles is 8000000 x (14950 / 23000) = 5,200,000.

Typically, the maximum frequency

for a 10,000 psi transducer is 50055 kHz.

At the maximum pressure (and the same temperature)

the number of reference clock cycles becomes 8000000 x (14950 / 50055) =

2,389,371.691. A digital counter cannot

count 0.691 clock cycles, so it will count either 2,389,371 or 2,389,372

cycles, depending just where in the 8 MHz pulse train the gate opened. The pressure variation represented by this

one cycle uncertainty is usually quoted as the sensor resolution, thus:

|

Resolution |

= Sensor Range x (1 / cycle count range) |

|

Or |

=

10000 x (1 / (5,200,000 - 2,389,372) |

|

Or |

=

10000 x (1/ 2,810,628) |

|

Resolution

|

=

.0036 psi |

It is clear that

resolution depends on:

(a) Time

available for measurement

(b) Reference clock frequency

(c) Dynamic range of the sensor

The

measurement time can be adjusted to make the best use of the sensor sampling

rate. Using the 8 MHz clock and by

sampling at least three second intervals, the resolution on the above sensor

will be better than .001 psi. According to some schools of thought, resolution

should be represented by the RMS deviation from the "correct"

calculated pressure, which leads to figures some 2 to 3 times more optimistic

than the ones shown.

Characterization

We use a

hybrid polynomial/look-up table characterization scheme. The program looks up the nearest four known

calibration points at each of the next two calibration temperatures above and

below the well temperature, and performs a local two-dimensional polynomial

approximation. This method has the

advantages that the characterization error is by definition zero at the calibration

points, and it is an order of magnitude less than that of a global polynomial

at intermediate points. It also allows

calibration down to atmospheric pressure without the risk of higher readings

being skewed by non-linearity at the bottom of the range; and it allows

reasonable extrapolation at temperatures below the lowest calibration

temperature.

It is

recognized that reference crystals are affected by temperature. We characterize each sensor over temperature

with its associated sensor-processor module, ensuring that the overall

characterization takes into account variations in reference oscillator

frequency.

The raw

sensor frequencies as measured at calibration time are stored in EEPROM in the

sensor-processor module itself, along with the calibration date. If the surface computer does not contain the

current calibration file for the tool at the data upload, the calibration

information is automatically uploaded.

The storage of raw information rather than polynomial coefficients

permits after-the-fact choice of characterization scheme. It also allows for reprocessing data after

re-calibrating the tool.

How do memory logs work?

Tubing

Checks - Leak Detection - Gas Lift Analysis

An excellent use for the

Slicklogger® PLT Systems is to perform tubing checks. It is a quick, economic, and accurate means of identifying tubing

leaks, gas lift leaks, and inoperative gas lift valves. Tubing leaks can be found by mechanical

means but this usually takes days to complete.

The initial costs associated with the mechanical methods are lower and

can appear to be the most cost effective; however, they rarely are, due to the

amount of time needed to define a depth range of +/- 20 feet. PL can tell you within a foot.

Other

practices of data acquisition for gas lift analysis are being replaced by the

dynamically acquired pressure data from a dedicated logging system. Stationary pressure gradient stops have been

used since the conception of pressure gauges (bombs). It is normal procedure to

make gradient stops in and around gas lift mandrel at 500' increments. If you really want to narrow in, you might

have the stops 100' apart in critical areas.

Thus, your resolution of data points is 100 - 500'! The Slicklogger® Systems will supply you a

data point on a per foot basis. In

addition, the other sensors in the tool can identify the conditions within the

tubing at the time the data is acquired.

You don't have to settle for stationary readings 500' apart where your

only control factor is to take long-term reading so that you can average the

data and guess at the conditions during acquisition.

Locating Water Source With Temperature Logs

Production

Logging actually began in the late 1930's with the introduction of temperature

measurements in oil and gas wells.

Production logging strings have become more sophisticated at qualifying

and quantifying flow profiles in the wellbore.

Basically, the production logging string obtains a density and a flow

velocity measurement that are then introduced to programs that will calculate

where the fluid is entering, the type of fluid, and the quantity of the

entry. Flow characteristics such as

turbulence, circulating fluids, and slugging can influence spinner and density

type sensors rendering the data useless for analysis.

Although

very accurate and reliable, temperature is often neglected as the proper tool